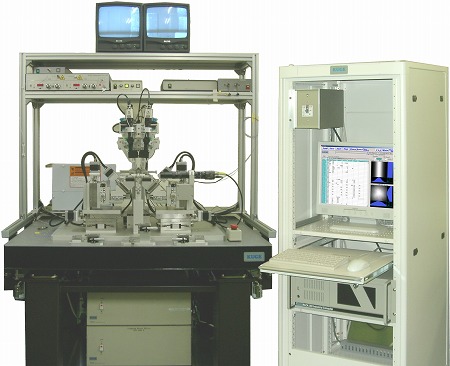

KS-502-AA PLC alignment system

Exterior (appearance)

Features

Feature 1

Because of the rigidity adopted SUS-made stage, make for a stable alignment disturbances such as

temperature and vibration.

Feature 12

Motion made by our control program "Cockpit" performed by aligning high.

"Cockpit" Because you can customize for your own use, the type of optical device, it is possible to

construct an environment for optimum alignment conditions and quality of various optical devices.

Specifications

| Device mechanism | 15 Axis Automatic (your special specifications are available) * Holders of the waveguide array and is interchangeable |

| Control Software | Motion Control Cockpit (additional type optical tracking software) |

| Computer built in device | Motor control board / A/D board / image board |

| Stepping motor driver | 15 Axis(corresponding to micro) |

| O/E converter | Optical power of optical fiber voltage conversion |

| I / O relay BOX | To control the shutter and the UV light source bulb dispenser. |

| UV light source | The computer I / O to control. |

| Dispenser | The computer I / O to control. |

| Anti-Shake base | Anti-Shake base mounting unit with arm |

| Computer | WindowsPC |

| Items | Distance | Resolution | |

| Movement of the array emission | X stage | ±25mm | 0.025μm |

| Y stage | ±15mm | 0.025μm | |

| Z stage | ±25mm | 0.025μm | |

| θx stage | ±8° | 0.00078° | |

| θy stage | ±8° | 0.0006° | |

| θz stage | ±8° | 0.0006° | |

| Movement of the injection array | X stage | ±25mm | 0.025μm |

| Y stage | ±15mm | 0.025μm | |

| Z stage | ±25mm | 0.025μm | |

| θx stage | ±8° | 0.00078° | |

| θy stage | ±8° | 0.0006° | |

| θz stage | ±8° | 0.0006° | |

| Emitting dispenser | Z stage | 60mm | 0.1μm |

| Incident dispenser | Z stage | 60mm | 0.1μm |

| Observing system / UV curing unit |

X stage | 100mm | 0.025μm |